Gewinde- und Profilwalzmaschinen

PEE-WEE® CNC AC Single- or Double Slide Cold Forming Machines are showing the proven rigid design with linear guides, available from 10to to 100to forming force. They are equipped with 1 or 2 CNC controlled hydraulic roll form slide axis and 2 AC servo motor driven shafts.

Machines with 2 CNC guided hydraulic slides are designed for improved handling and set up. Any loading device is always positioned in the centre of the machine. This guarantees perfect conditions for installing automation and/or robot systems supporting the open work space for easy access.

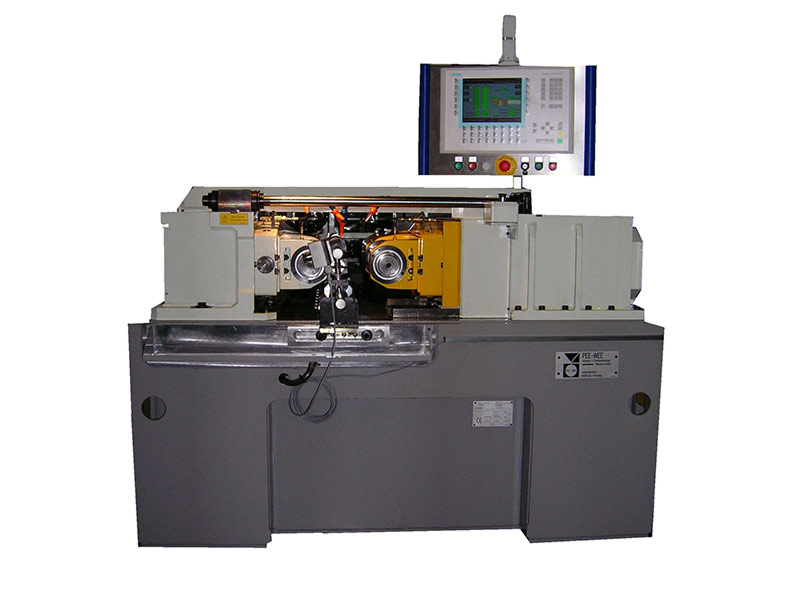

P15 CNC AC

P30 CNC AC

P80 CNC AC double slide

Technische Daten der verfügbaren Modelle:

| Model | Forming force | Tool o | Shaft o | Support length | Work piece o | Weight |

| P 5 CNC-AC | 10 - 50 kN | 90 - 110 mm | 40 mm | 60 mm | 0 - 25 mm | 800 kg |

| P 10 CNC-AC | 10 - 100 kN | 130 - 180 mm | 54 mm | 120 mm | 3 - 40 mm | 1.200 kg |

| P 15 CNC-AC | 10 - 150 kN | 130 - 200 mm | 54 / 69,85 mm | 180 mm | 4 - 50 mm | 2.000 kg |

| P 20 CNC-AC | 10 - 200 kN | 130 - 200 mm | 54 / 69,85 mm | 180 mm | 4 - 50 mm | 2.300 kg |

| P 24 CNC-AC | 10 - 240 kN | 160 - 200 mm | 69,85 / 80 mm | 230 mm | 4 - 120 mm | 3.600 kg |

| P 30 CNC-AC | 10 - 300 kN | 160 - 280 mm | 80 / 100 mm | 230 mm | 4 - 120 mm | 4.000 kg |

| P 40 CNC-AC | 10 - 400 kN | 160 - 280 mm | 80 / 100 mm | 230 mm | 4 - 120 mm | 4.400 kg |

| P 50 CNC-AC | 50 - 500 kN | 160 - 280 mm | 100 mm | 250 mm | 4 - 240 mm | 7.500 kg |

| P 60 CNC-AC | 50 - 600 kN | 160 - 280 mm | 100 mm | 250 mm | 4 - 240 mm | 8.000 kg |

| P 85 CNC-AC | 50 - 850 kN | 160 - 280 mm | 100 / 120 mm | 250 mm | 4 - 300 mm | 11.200 kg |

| P 100 CNC-AC | 50 - 1000 kN | 160 - 280 mm | 100 / 120 mm | 250 mm | 4 - 300 mm | 12.800 kg |

PEE-WEE® CNC Standard cold forming machines with rigid full cast design and dove tail guide ways are offered from 15to to 35to capacity. They are perfectly manufactured for threads, profiles and serrations (optionally accessory with "hydraulic back lash compensations"). The roll form slide axis is CNC controlled.

The SIEMENS SPS S7 control with PEE-WEE® Software, the frequency converter for infinitely variable speed regulation and the SPS integrated quality assurance system are a part of the basic equipment of this model range. For comfortable set-up the software includes different pre-set forming programs.

P15 CNC with automation

P24 CNC

Technische Daten der verfügbaren Modelle:

| Model | Forming force | Tool o | Shaft o | Support length | Work piece o | Weight |

| P15 CNC | 10 - 150 kN | 130 - 200 mm | 54 / 69,85 mm | 180 mm | 4 - 50 mm | 2.400 kg |

| P20 CNC | 10 - 200 kN | 130 - 200 mm | 54 / 69,85 mm | 180 mm | 4 - 50 mm | 2.400 kg |

| P24 CNC | 10 - 240 kN | 130 - 200 mm | 54 / 69,85 mm | 180 mm | 4 - 50 mm | 4.000 kg |

| P30 CNC | 10 - 300 kN | 160 - 220 mm | 69,85 / 80 mm | 230 mm | 4 - 120 mm | 4.000 kg |

| P35 CNC | 10 - 300 kN | 160 - 220 mm | 69,85 / 80 mm | 230 mm | 4 - 120 mm | 4.400 kg |

The UPW® LOW COST line convinces by an excellent price-performance-ratio, available from 5to up to 100to. There is more power on request. All models are equipped with SIEMENS SPS control and frequency converter (FU) for infinitive variable speed.

AThe universal composition allows the application of the machine for all known processes of forming in in-feed or throughfeed. Highest production rates can be realized. Manual loading and unloading supported by the generous working space.

The automation of this model range is always possible because of the open construction of the working space and makes the handling easy. This reduces the bottom to bottom time and simplifies loading and discharging of the work pieces.

High precise profile guiding rails lead to higher quality in through-feed or in-feed are guaranteed process. Thanks to ECO-SYS short changeover times are guaranteed. All adjustments are easily done from the front of the machine.

P15 CNC AC

P30 CNC AC

P80 CNC P80 CNC AC double slide

Technical Data:

| Model | Forming force | Tool o | Shaft o | Support length | Work piece o | Weight |

| UPW® 5 | 10 - 50 kN | 90 - 110 mm | 40 mm | 60 mm | 0 - 25 mm | 980 kg |

| UPW® 10 | 10 - 100 kN | 130 - 180 mm | 54 mm | 120 mm | 3 - 40 mm | 1.400 kg |

| UPW® 15 | max. 150 kN | 135 - 230 mm | 54/69,85/80 mm | max. 200 mm | 2 - 55 mm | 2.600 kg |

| UPW® 20 | 10 - 200 kN | 130 - 200 mm | 54 / 69,85 mm | 180 mm | 4 - 50 mm | 2.600 kg |

| UPW® 24 | max. 240 kN | 135 - 230 mm | 69,85/80 mm | max. 200 | 2 - 55 mm | 2.900 kg |

| UPW® 30 | max. 300 kN | 150 - 260 mm | 80/100 mm | max. 225 mm | 2 - 150 mm | 4.600 kg |

| UPW® 40 | max. 400 kN | 150 - 260 mm | 80/100 mm | max. 225 mm | 2 - 150 mm | 4.800 kg |

| UPW® 50 | max. 500 kN | 150 - 280 mm | 100 mm | max. 250 mm | 2 - 240 mm | 7.500 kg |

| UPW® 60 | max. 600 kN | 150 - 280 mm | 100 mm | max. 250 mm | 2 - 240 mm | 7.800 kg |

| UPW® 85 | 50 - 850 mm | 160 - 280 mm | 100 mm | 230 mm | 4 - 250 mm | 9.800 kg |

| UPW® 100 | 50 - 1000 kN | 160 - 280 mm | 100 / 120 mm | 240 mm | 4 - 250 mm | 10.800 kg |